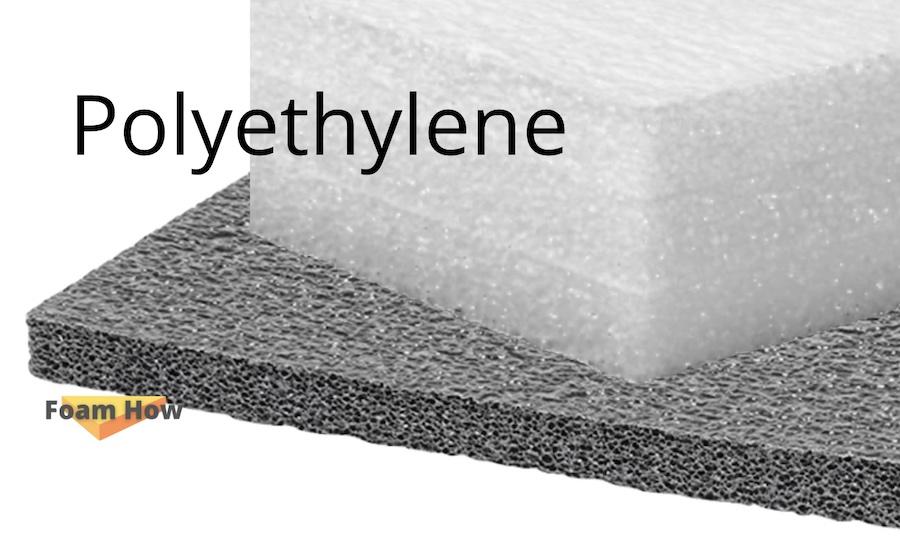

Polyethylene foam is something you’ve probably all handled at some point in our lives, but perhaps we didn’t realize it. So what is polyethylene foam?

Here’s the guide on what Polyethylene foam is, the common uses and features it has, and how it’s made. Let’s start with a quick summary…

Polyethylene foam is a lightweight, tough, resilient, and odorless closed-cell material. Often used for packaging heavy goods due to its firmness, or fragile goods, due to high impact absorption, and offers good insulation. It is resistant to chemicals, fluids, and moisture, and cheap to produce.

That’s the brief answer, but would you recognize it if you saw it? After you’ve read this then the answer will probably be yes. Let’s dive into this topic further.

What is Polyethylene Foam?

The Manufacture of polyethylene foam is not too dissimilar to that of most other foam. It’s due to slight changes in process and some additional additives that create a tougher yet slightly more abrasive texture to the foam.

Like many foams, Polyethylene is a closed-cell foam. The structure consists of millions of small sealed bubbles that are closed off from each other, hence “closed-cell”.

This structure provides a robust strength to the material and also gives it some of its features such as water resistance. More on features shortly.

Polyethylene foam has numerous applications largely due to its high resiliency properties. It returns to form after compression, and It can be stored for years – even in a compressed form – without degrading, and still, often return to its former shape.

Polyethylene foam is easy to cut, shape, and easy to manufacture.

How Polyethylene foam is made

Polyethylene foam is a result of the heating of polymer compounds. During this process, additives can easily be applied to the material formula to create varying effects on its properties.

Following the correct balance of additives, it is then heated and extruded to create a solid form.

Some additives can include anti-static formulas to produce other forms than the standard sheets. For example, anti-static polyethylene foam is created by some additives in order to dissipate static charge around delicate electronic goods and instruments. The same can be done to apply fire retardancy features.

Unlike some other foam, these additives can be applied before heating and extruding, so the formula runs throughout the foam, rather than simply added to the surface.

Density and firmness of Polyethylene foam

Like most foams, polyethylene foam can be cut and shaped to size by suppliers. At the manufacturing stage, it can be formed into not only various shapes, but with varying degrees of density.

Density, along with firmness, is an important factor in the makeup of any foam. You can find out more about firmness and density here.

The density of polyethylene foam ranges between 2.2 lb to 9.0 lb. 9.0 lb is a density rating of 90, which is considered very dense.

In short, the higher the density of polyethylene foam, the heavier the foam. The heavier the foam is the greater quality it has. Higher density equates to smaller cells, and thicker cell walls creating a more dense and stronger material.

Polyethylene foam common uses

Polyethylene foam has a plethora of uses, most of them are low-level uses rather than high-end uses, so you’re unlikely to find them at the heart of a mattress or a sofa. Nonetheless, the uses are extensive.

- Packaging for heavy goods, electronic products, tools, and machinery

- Flotation devices such as pool noodles and rescue floats

- Masonry raw material protection

- Floor underlay

- Shock absorbers to protect from impact

- Anti-static protection for electronics and electrical components

- Surface protection

- Sports & leisure apparatus such as archery targets and cones

- Insulation applications

- Medical

- Construction as use for void fillers

- Military applications

- Floor underlay

- Agriculture applications

Amazon options for Polyethylene foam

Polyethylene foam features

Here’s a list of features that accompanies polyethylene foam. The list of positive features is quite extensive.

- Closed-Cell

- Very lightweight

- Mostly non-abrasive

- Easy to fabricate

- Does not shed particles

- Odorless

- Resistant to tearing

- Shock absorbency

- Highly buoyant

- Thermal insulation properties

- Vibration dampening properties

- High flexibility

- Acid free

- Protected against mildew, mold, rot, and bacteria

- Resistant to water and moisture

- Antimicrobial and anti-bacteria properties

- Resistance to chemicals, petroleum, grease, and solvents

- CFC free

- Cost-effective

Amazon options for Polyethylene foam

Is polyethylene foam toxic

Polyethylene foam is classed as non-hazardous. Specifications detail this type of foam as having no physical or chemical hazards. No significant environmental hazards.

However, when concerning fire retardant and noxious vapours, it was seen as potentially causing respiratory tract irritation when melted.

Certifications are available here.

For the use of polyethylene as insulation in ceilings or homes in general, Polyethylene foam is available in both fire retardant and non-fire retardant forms. A reputable foam supplier will be able to assist you in obtaining the correct type.

Let’s go on to answer some common questions asked about Polyethylene foam…

Amazon options for Polyethylene foam

Is polyethylene foam recyclable?

Polyethylene foam is 100% recyclable globally. It can be melted down and reused and remolded for similar applications such as rubber insulation. Expanded Polystyrene (EPS) is also 100% recyclable globally.

Is polyethylene foam biodegradable?

As with most plastics, polyethylene foam is not biodegradable. They will take many hundreds,if not thousands of years to biodegrade in a natural environment. Polyethylene can and should be recycled.

Polyethylene foam UV exposure

Standard Polyethylene foam is susceptible to extended UV exposure. Covering the foam, or painting it with latex based paints are recommended to extend the life of polyethylene foam. Fire retardant versions are less susceptible to UV.

A UV resistant fabric could be glued or applied to the polyethylene foam surface.

Does polyethylene foam absorb water?

Because polyethylene foam is a closed cell foam it is sealed and therefore waterproof. Polyethylene foam is often used for floatation devices and products because of the is reason.

A UV resistant fabric can be applied / glued to the surface of the polyethylene foam..

Polyethylene sheets as underlay

Sheets of polyethylene are often used as carpet underlay. They are robust enough to withstand years of wear and tear.

Polyethylene as insulation

Polyethylene foam can be used for insulation applications. It is effective at maintaining a barrier between temperatures, for thermal insulation or refrigeration such as cool boxes.

At the same time, Polyethylene is effective as a vapor barrier to prevent moisture penetrating walls and surfaces. Even sheets as thin as 3/8-inch can be sufficient closed cell barriers against vapor.

Polyethylene and sound proofing

While polyurethane acoustic foam is better suited for sound absorption, polyethylene can be used as an effective sound barrier and sound dampening material. Even thin polyethylene rolls offer some sound proofing qualities.

See my article on package wrap foam for more information.

Is polyethylene foam flexible

In general, the thicker polyethylene foam is, the harder it is to roll. Sheets of 1-1/2-inches with a 2.2 density grade or less have greater potential to be rolled and are certainly more flexible.

Amazon options for Polyethylene foam

More foam help

I hope this has provided a good overview to answer the question of what is polyethylene foam. Be sure to check out my article concerning other types of foam.