You’ve perhaps heard the term closed cell foam before, but now maybe you have a project and need to understand more, and therefore find yourself asking what is closed cell foam?

Having done the research, I’m going to provide the answers for you. I’m outlining what closed cell foam is, the types of closed cell foam, the uses, and the pros and cons. Then I’ll finish with the comparison between closed cell foam and open cell foam. Here’s the quick summary…

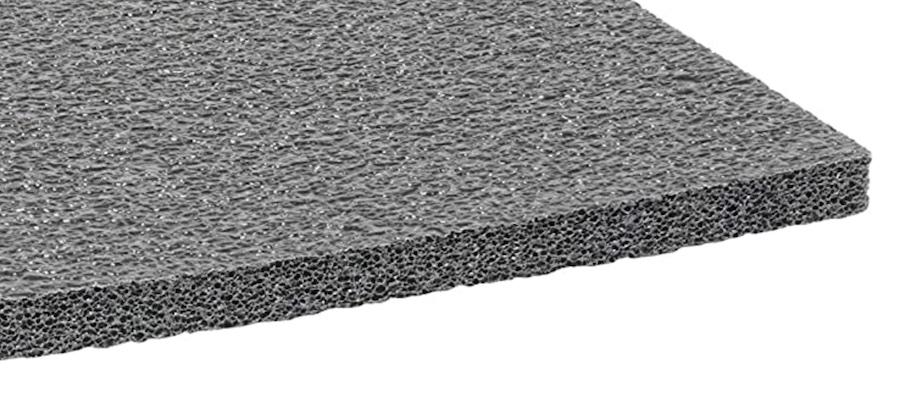

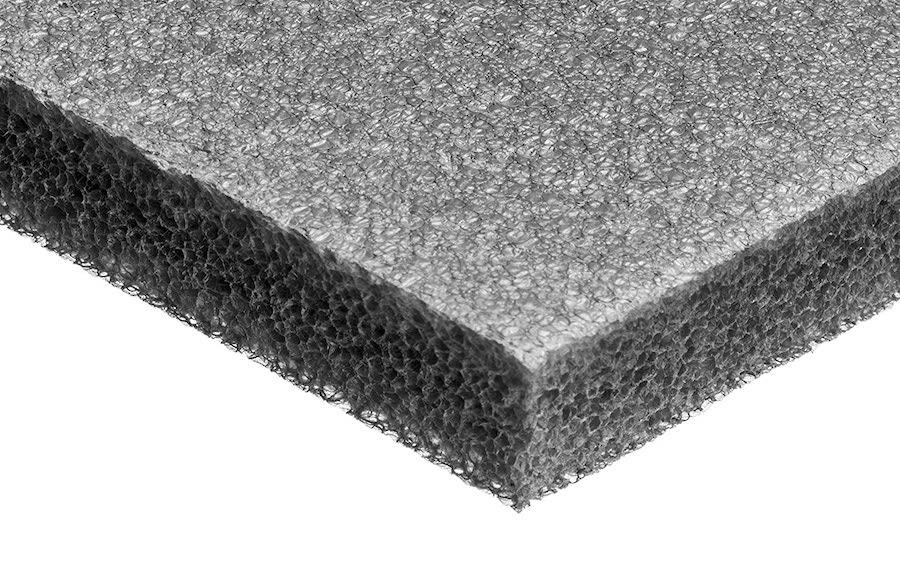

Closed-cell foam is a rubber compound developed under gas pressure. Set apart from other foams by having cells that are similar to small gas-filled bubbles. Closed-cell foam is generally waterproof, highly durable, easy to manipulate, and comes in many shapes and sizes.

Closed cell foam is defined as a tightly knitted foam, totally enclosed by its walls. It’s made by subjecting a rubber compound to a gas under high pressure, such as nitrogen. Closed cell foam offers a wide variety of material and density options.

All types of foam, if looked at closely are made up of tiny irregular spheres, or bubbles. It’s more a case of how tightly packed they are – which defines their density and rigidity, and whether there are gaps that are water-permeable or not…

The close-knit bubble characteristics make closed-cell foams much more durable and appropriate for heavy use applications that require moisture resistance.

How closed cell foam is made

The manufacturing process of closed cell foam consists of applying a gas – mostly nitrogen, to plastic and/or rubber compounds under high pressure.

The gas is pumped under high pressure into the liquid mixture of the material which then creates a tight cellular structure that closely resembles a smaller version of a bubble wrap construction.

The process can be separated into two methods:

- By exposing the material to the gas directly

- By adding gas-forming agents into the material

A wide and varying range of closed cell foams is available in the market with options of different kinds of materials and densities …catering to the different needs and demands of buyers.

Since this type of foam is offered in different types and for different and multipurpose use, industries such as automotive, medical, sports, and even construction, to name a few, benefit from closed cell foams.

Different types of closed cell foams

As mentioned previously, closed cell foams come in a variety of forms, often with different and overlapping names, serving different needs and demands. It can even sometimes be hard to tell each foam apart as the manufacturing differences and benefits can be subtle. Below are a few of the options available on the market.

Polyethylene foam

Sometimes called ethafoam, this type of closed cell foam is designed to be strong, sturdy, and resistant against water and other liquids, which means it is also stain resistant.

Moreover, it has the ability to remain afloat, reduce sound, and has good shock absorption. These characteristics make closed cell foam ideal for packaging, medical and delicate packaging, and for use in arts and craft projects. Available in multiple shapes and sizes on amazon such as this polyethylene foam sheet example.

You can read more about Polyethelene here.

Polyethylene rolls

Closed cell foam can also be formed into polyethylene rolls, however, when used in rolls, even though it is still effective for certain tasks, it is less effective in thinner rolls in comparison to the strength and durability of thicker versions.

Closed cell foam roll is often used for plumbing and piping purposes, medical supplies and other health care items, for sports products, and even by the automotive industry. You can get a variety of shapes, types, and thicknesses, such as the Polyethelene foam tubing example below from Amazon.

Cross-Linked Polyethylene

Cross linked foam is a type of closed cell foam. It is also a thick and sturdy variety, which can be beneficial for numerous applications.

Alongside that of being water, air, and stain-resistant, this type of foam is also resistant toward mildew and mold.

Cross-linked polyethylene has another advantage in that it has a good appearance compared to other foams, making it an ideal option for packaging requirements for branded products.

This option is also commonly used for floatation devices, packaging, and construction use. Here’s a good example of Cross Linked Foam available on Amazon.

There is also non-cross linked polyethelene (PE) foam…

Difference between cross linked and non-cross linked foam

Cross-linked (PE) foam has a more uniform and finer, regimental cellular structure. Non-cross-linked (PE) means the polymer chains are not linked to one another. It is more recyclable, easy to manipulate, and less abrasive. Both are closed cell, are waterproof, and provide similar benefits.

Polystyrene foam

Most of us are familiar with polystyrene. Polystyrene is a closed-cell foam available in numerous shapes, such as blocks, spheres, sheets, etc, and can be sold as single units and even multi-packs – depending on the quantity and application it’s required for.

The option of multiple densities is also available with this type of closed cell foam in order to cater to varying needs.

Some of the ways this type of foam can be used are storage and packaging purposes. Here’s an example of polystyrene sheets from amazon.

You can explore a quick list of all the different types of foam and their general uses in my article on types of foam.

Now let’s get on to the pros and cons of closed cell foam…

Pros of closed cell foam

Coming in various forms and different types of usage, closed cell foams come bearing a variety of benefits, some of which include:

- Closed cell foams to a large extent are waterproof. Since the cells in this particular kind of foam are so closely packed together, they leave little room for water to seep in. This logic applies to all materials that have a cellular structure tightly knitted together, making them highly water-resistant.

- Closed cell foam pores have the ability to self-clean. This ultimately helps in avoiding glazing.

- The material is light yet strong which makes it tear-resistant, meaning closed cell foams are more durable and long-lasting.

- Closed cell foam is tougher and more rigid. Due to its greater rigidity, closed cell foam tends to be a tougher material than open-cell foam and generally maintains its shape for longer.

- Excellent insulation properties. Just as closed cell foams are waterproof due to their tight cellular structure they also act as an air barrier, so they can provide good insulation properties.

Cons of closed cell foam

Closed cell foams, although highly beneficial, do come with a few drawbacks that should be kept in mind when purchasing or using them in products

- Lower shock absorption. The shock absorption ability of a closed cell foam may be lower than that of an open-cell foam due to its tight cell structure

- Closed cell foams are less “breathable”, especially compared to open-cell foams

- Will not fill smaller holes. Because closed cell firm is rigid, it’s less effective at filling every cavity when the cavity is small. It’s more of a rigid glue than a gap filler.

- Higher density and can break. Another disadvantage of closed cell foam is its higher density. This means that the foam – even though it comes with varying levels of densities, is quite firm and rigid when compared to the other conventional available options.

Closed cell foam vs open cell foam

Closed cell foam and open-cell foam are both available in multiple varieties and offer a variety of uses. However, before deciding which option to go for, it’s essential to understand what sets them apart and what best fits your needs

The first difference between the two foams is quite an obvious one.

As their names suggest, closed cell foams have a tight and closely packed together cellular structure whereas an open-cell foam has a cellular structure that is more scattered and broad.

This means that due to the cell structure of open-cell foams, they are prone to absorbing air, which provides them with a more breathable feel. However, closed cell foams are firm and rigid which provides their air resistance abilities.

Another difference between open and closed cell foams is that the open cell has the tendency to be springier and bouncy but cracks easier, while the latter has little spring in them and is quite firm and rigid and non-forgiving.

Use differences for open cell and closed cell foams

These foams are quite unlike each other and are used quite differently. Closed cell foams are ideal for uses that require a sturdier option such as in packaging and protecting fragile items.

Another use for closed cell foams is within the construction industry where it is used for insulation purposes due to its ability to trap heat or for air conditioning thanks to its air resistant qualities.

Whereas, since open cell foams have a softer and lighter feel to them, they are commonly used for their comfort properties such as in cushions, sofas, mattresses, and even commercial uses such as car seats.

It should be taken into account, that for the foam to be classified as open-cell foam, it doesn’t necessarily have to have all present cells open. Foam can be labeled as an open cell foam even if it has equal parts of closed and open cells.

This however means that even though these types of foams are softer than fully closed cell foams, they are still much more firm compared to fully open-celled foams.

To finish then…

I hope this has helped answer the question of what is closed cell foam. Be sure to check out my other articles to increase your foam education for any projects you might have.