Maybe your project calls for dry fast foam, and now you find yourself asking – what is Dry Fast foam?

In the vast and diverse world of foam, Dry Fast is really one-of-a-kind. It’s one of the most porous foams available on the market, mainly due to its cellularly connected property, which I’ll explain shortly. But first, here’s a quick summary answer and then I’ll dive into the details…

Dry Fast foam is a durable foam perfect for wet or damp environments such as marine applications or outdoor seating. It does not retain water or moisture and has antimicrobial properties to prevent rot or mold growth. It is also known as Quick Dry, Ever Dry, Easy-Dry, or Calipore foam.

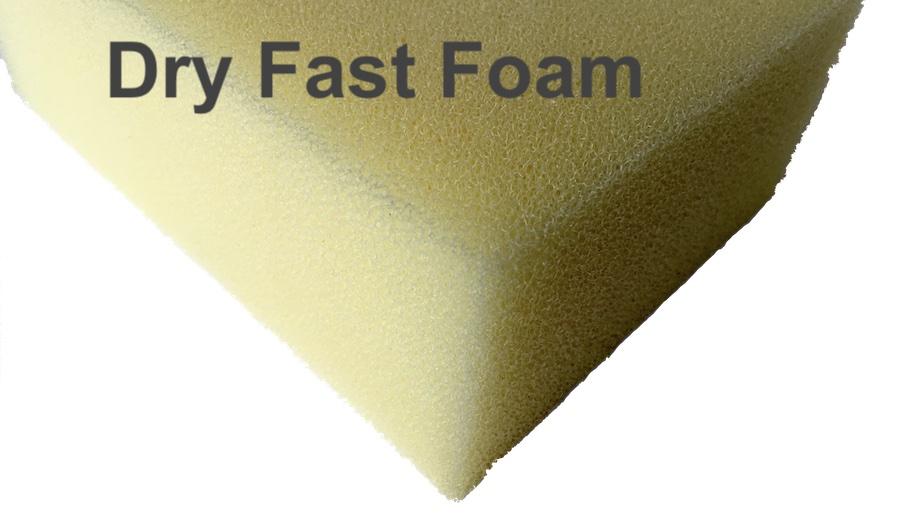

With most foams, from even a short distance away, you would barely be able to see any of the tiny cells that make up the structure of conventional polyurethane foam.

Dry Fast foam, on the other hand, has a broader, more fibrous structure, with visible, uneven and loosely aligned cells even from a distance.

Standard open-cell polyurethane foams have cells that are fractions of a millimeter in diameter, while Dry Fast may have cells as wide as five millimeters in diameter, depending on the formulation.

Here’s a close up image I’ve taken of Dry Fast foam to give you an idea of the open structure…

Why Dry Fast foam dries fast

Traditional foams act spongy, which is true in terms of both feel and comfort.

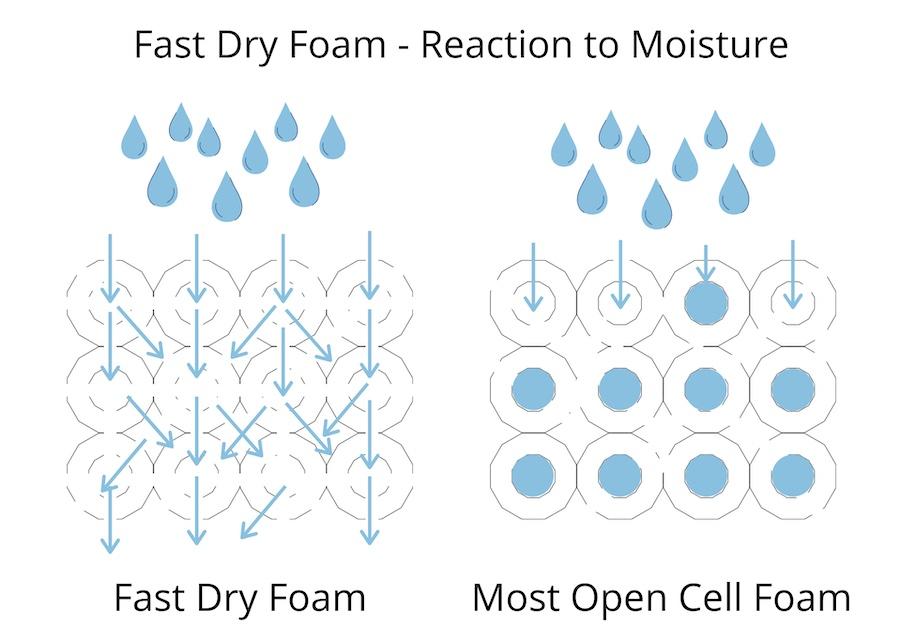

Dry Fast foam is also “spongy” in terms of its feel, but most foams retain a lot of water because of their interconnected cells, which produce a capillary effect. This is essentially a wicking effect where a material draws a liquid in and retains it.

Here’s a simple diagram explaining how most foam reacts compared to Fast Dry Sponge…

This isn’t necessarily a good thing, because foam that holds moisture will likely rot faster, produce bacteria, and grow mold.

This is important for boat owners who would be concerned about getting waterlogged cushions. Foams can be destroyed by being left outdoors during even a single rainstorm.

However, Dry Fast foam doesn’t work the same as most foams. Its water-resisting capabilities make it popular among boaters and for other outdoor uses.

Advantages of Dry Fast foam

Here are some of the main advantages of Dry Fast foam, and the main reasons why it’s used in moisture-rich conditions…

Antimicrobial properties

Dry Fast foam thrives under damp or wet conditions. Water and air pass easily through its porous structure, resulting in a cushioning substance that does not retain water and dries rapidly when wet.

During manufacture, Dry Fast foam is impregnated with ingredients that provide antimicrobial properties – to help it withstand the effects of trapped moisture in the foam.

This is very important because, although the foam is built to dry quickly, external factors may quickly degrade its ability to do so.

Wet towels left on a cushion …or the cushion being put on a surface that does not allow airflow for drying may prevent moisture from evaporating.

When this happens, Dry Fast’s antimicrobial properties prevent the growth of irritants that might otherwise destroy your custom cushions or seating pads if moisture gets inside.

Dry Fast foam is easy to clean

These foams are much easier to clean when required, in addition to not harboring irritants. Even though they are rarely exposed to moisture, traditional foams will trap some dirt, dust, and other particles.

You won’t be able to pull all these particles out of most foams once they’ve become deeply embedded into the structure of the polyurethane foam. But that’s not the case for Dry Fast foam.

You can easily clean Dry Fast foam…

To clean Dry Fast foam, remove any outer covers from the foam and hose the foam off well. Blasting with water can help. Then position the cushion in a dry, well-ventilated environment inside or outside. It should be dry within 24 hours. Indoor fans or sunlight can speed up the process.

In the first instance, you may want to obtain breathable and durable covers for your outdoor seating to put your dry fast foam into. These are usually Phifertex or Sunbrella – which tend to be my favorite designs.

These kinds of fabrics, designed specifically for damp and wet environments are available in a multitude of colors and styles on Amazon.

Is Dry Fast foam easy to work with?

Installing any seat cushions or marine foam cushions within your boat is certainly not an easy task, and Dry Fast foam is really no different.

The most important thing is to weigh the foam you’ll need and cut it into the sizes required. You may also play with blends of foams to see which one fits best.

Whatever the use, for any moisture rich environment, dry fast foam is the most effective way to extend the life of your boat cushions or outdoor seat pads, while still increasing comfort.

The manufacturing process of dry fast foam

The manufacturing process for Dry Fast outdoor foam sets it apart from other polyurethane materials. And actually, the method is quite impressive.

Dry Fast starts out like any other foam, with cellular walls forming panes in a 12-sided geometric pattern.

After the basic form is finished, the material is subjected to one of two additional processes in order to achieve the material’s distinctive wide-open shape. Each method is used based on what the foams intended purpose is to be.

Quenching

First, it undergoes a chemical process known as quenching.

Foam is passed through a bath of caustic fluid at predetermined levels of pressure, temperature, and immersion time.

The foam is submerged in the fluid for a long period of time to break the thin cell walls, also known as “windows”. Struts are the foam components that hold the foam together.

Zapping

The second method is known as zapping.

In this thermal-based method, the basic foam shape is placed in a vacuum-sealed tube, which is then pumped with a specially formulated reactive gas mixture.

In this vacuum-sealed room, an explosion or spark occurs, resulting in a fast-moving but controlled flame that passes through the foam almost instantly.

The flame melts the thin windows but not the struts …because it isn’t present quite long enough to destroy the integrity of the whole structure.

Resulting characteristics and uses

Despite the fact that both methods manufacture reticulated foam, the two materials have somewhat different characteristics.

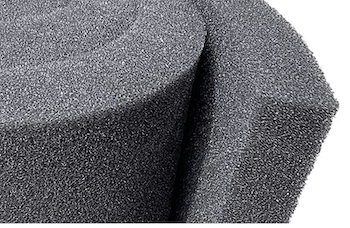

Fewer windows are replaced when the foam is quenched, and some of the thicker panes are only partially melted. Owing to the increased material volume, this will help trap and preserve debris, making it ideal for filtration-based applications.

Filter based Fast Dry foam

Here’s an example of Dry Fast foam made specifically for aquariums and other filter-based uses. You might struggle to see the difference, but this has been “processed” less than Fast Dry seating foam. You can get this filter based foam on Amazon too.

Zapping results in a cleaner structure, when the fire melts the struts smoothly, they result in cleaner struts. This type of quick-dry foam allows the most amount of air and fluid to pass through it, which is therefore perfect for damp and wet environments such as outdoor seating.

The next time you need foam for a job, bear in mind that every foam is unique.

As a result, there is a good chance that your foam will not perform well in at least one application – that perhaps it wasn’t intended for.

Dry Fast foam is a perfect match for anywhere there is water or a propensity for moisture, and it comes with a design also built to ensure comfort.

This foam is a safe way to prevent moisture-related problems in vessels and other marine applications. Despite the fact that it hasn’t been fully tested for use in marine aquariums, it has a wide variety of applications to suit your needs.

Ultimately, the main difference is that this type of foam has a wide open-cell design that allows for exceptional airflow – not seen in most other types of foam, allowing it to dry much faster.

Most significantly, it is antimicrobial, which helps to kill and avoid the growth of bacteria and fungi, which can be a major concern in damp areas.

This foam is a perfect option for sea boats, patio seat cushions, and bedding for those with certain medical conditions. To help hone down what you’re looking for, here’s a selection of the available sizes and thicknesses of Dry Fast foam on Amazon.

To close

I hope this has helped answer the question of “what is Dry Fast foam”. Be sure to check out my other articles to learn more about which foam is right for your projects.