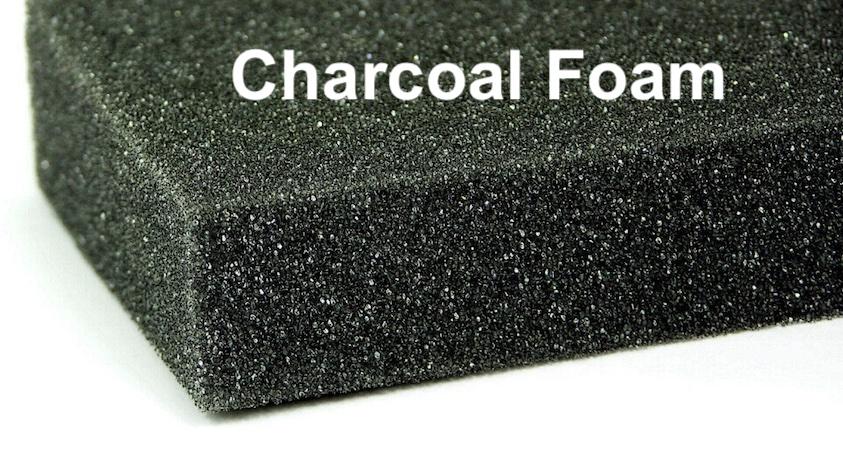

We’ve all encountered charcoal foam, also called gray foam, at some point or another. It’s a very common type of foam and there are a few versions of gray foam you’ve probably come across. But what is charcoal foam?

Here’s the guide on what charcoal foam is, how it’s made, the features and benefits, as well as all the common uses of charcoal foam. Starting with a quick summary…

Charcoal foam is a low density and low firmness, lightweight open-cell foam. It has good airflow, is durable, stain, impact, and damage-resistant which is good for packaging applications. It’s used for soundproofing and repels most dirt, making it easy to clean. It is cheap and easy to cut.

Charcoal foam – background

Charcoal foam, as the name suggests, is a type of foam. To be more precise, charcoal foam is made using an open-cell structure that allows excellent airflow for applications requiring free movement of air.

Enduring many distinct properties charcoal foam is renowned for being lighter weight in comparison to many other types of foam.

This property is what makes charcoal foam ideal for the shipping and packaging industry. However, charcoal foam is also widely used for many other applications within many other industries.

Common uses of charcoal foam

Primarily charcoal foam was used to design the inside of cases for electronic instruments and delicate hardware. This includes cases such as cameras, computers, and gun cases.

Aside from this, it’s also widely used for packaging shipping, warehousing, general handling, acoustic dampening, and soundproofing applications, such as for music studios and home cinemas.

It has lightweight and shock absorbent properties that are perfect for protecting fragile items such as wine glasses and bottle packaging, booklet advertising foam, guns, knife protection, electronic foam padding, and even custom tool padding.

They can be used to protect all lots of fragile equipment and industrial instruments during transit or while in storage.

Charcoal foam can also be cut into custom pieces (although it is relatively firm) for other specific uses.

For most project use, the best way to achieve this is by using a sharp bread knife – or an electric bread knife. Make sure you are cutting in one straight movement and direction to get a clean cut.

If this seems like a difficult task, you can get customized cuts from suppliers.

However, make sure that you’re specifying what you need the charcoal foam for. This is because there are many types of charcoal foam based on variations in density and firmness, and a reputable supplier will be able to advise accordingly.

Common features of charcoal foam

The common features of charcoal foam, mainly in reference to the regular charcoal foam are as follows:

- Lightweight

- Excellent airflow

- Low density

- Less firm than most other types of foam

- Durable and long-lasting

- Stain, impact, and damage resistant

- Sound dampening or soundproofing properties

- Easy to cut using a sharp knife or an electric turkey knife

- Lower priced than other types of foam

Remember that these properties, especially the price, may vary depending on the type of charcoal foam.

Types of charcoal foam

These days charcoal foam is becoming a more versatile option within the packaging industry.

This is because certain additives and other elements introduced to a basic form of foaming process can create specific properties over and above the basic foam. This makes it more suitable for specific purposes.

This is one of the reasons why you can get different types of charcoal foams on the market.

So depending on your purpose, you can always get a more suitable type of charcoal foam than just settling for a basic or regular one. Its recommended that you discuss your needs with a foam supplier who can suggest you the ideal charcoal foam type.

With that background in place, here are the three common types of charcoal foams you can choose from.

1. Soft charcoal foam

This is the regular – or the original – type of charcoal foam. Manufactured without further additives or enhancing properties. In this type, you can expect the basic properties of charcoal foam.

It has an attractive appearance, and because it’s difficult for the foam to soil or stain, it will retain the outer look or appearance for years.

This in general ensures high durability and a long-lasting solution for its applications. Regarding applications, this is more suitable for packaging options that need more protection, such as sound-deadening aids, engine covers (as long as it’s away from elements such as flames and oils).

Although this is a regular type of charcoal foam it doesn’t overlook the sound and impact control or absorbent properties which still makes it a versatile option for many applications.

However, generally, charcoal foam is lightweight and has a lower density altogether which may not give the best firmness or supportive properties as with many other types of foam.

eBay options for Charcoal foam

| Charcoal Foam | |

|---|---|

| Quality | Good |

| Weight (per cubic ft) | 1.8 lb |

| Structure | Open Cell |

| Density (range 1.0 – 6.0) | 1.2 – 1.6 (12-16) |

| Firmness (ILD) | 15 – 25 (soft) |

| Lifespan | 6 – 8 years |

| Colors | Charcoal |

| Applications | Auto compartments, Packaging, and shipping, Acoustic dampening |

2. Firm high density charcoal foam

As I alluded to before, because of low density, the regular charcoal foam will likely be less firm than most other types of foam. This makes it less suitable for applications where cushioning is involved, such as sofas, chairs, or beds, except where high firmness and density varieties are chosen.

This type of charcoal foam (or gray/grey) was produced where greater firmness and density are required for tougher and more harsh applications such as use in engine compartments.

This type of charcoal foam provides a firmer option to those who are specifically looking for greater firmness as a major characteristic of the foam.

This “gray foam” (or grey foam) provides the same performance as regular charcoal foam but with a greater degree of density and firmness.

This higher density and firmness make this type of charcoal foam more resistant to impact and damage in more harsh environments – where regular charcoal foam is unsuitable.

Extra firmness with gray foam also adds greater protection for its applications, especially for packaging.

This makes a perfect packaging solution for extra-sensitive objects like glassware. Also to mention, this higher density can also be used for sound deadening, if perhaps less so than the softer charcoal foam.

Amazon options for Packaging foam

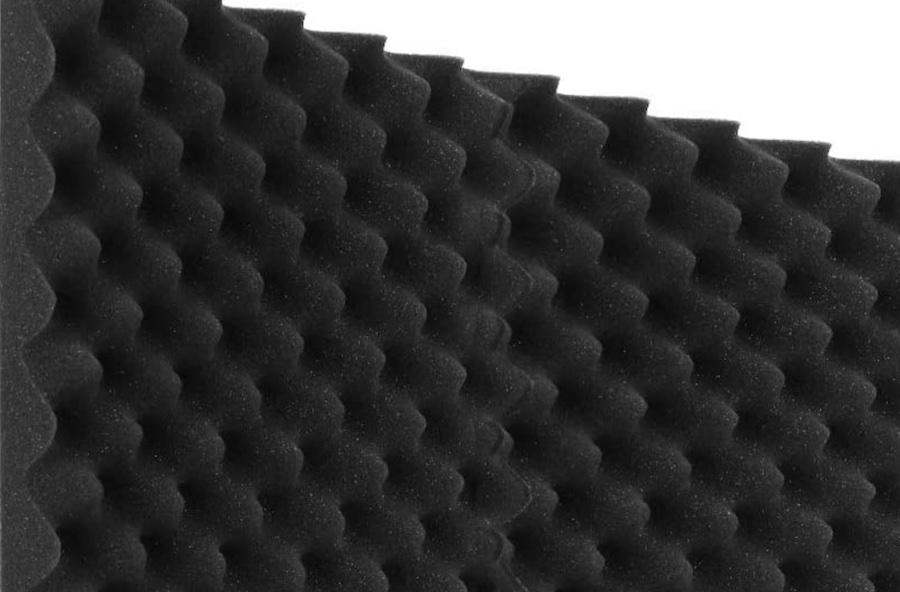

3. Egg crate foam

This is a type of charcoal foam that is manufactured with a raised, undulating surface. In contrast to the usual smooth surface that comes with other types of charcoal foam.

While a smooth surface can be more appealing to see and easier to work with, a raised surface offers unique benefits.

Firstly egg crate charcoal foam can still offer a great level of impact resistance. Meaning goods packaged using egg crate charcoal foam can resist impacts that come while shipping, storage, or transit.

The texture and appearance of this type are the same as other smooth surface types of charcoal foam, with the same stain resistance properties.

This type of charcoal foam is mostly used for shipping items like electronics and instruments.

Remember that egg-crate charcoal foam is only a difference in the surface. Meaning you can get egg crate charcoal foam with the same features as regular charcoal foam and the firmer packaging gray foam, depending on your needs.

This type specifically is provided as a separate product simply because of its unique raised surface and the related properties that provide.

amazon options for egg-crate foam

More foam help

I hope this has answered the question of what is charcoal foam. Be sure to check out other types of foam to ensure you get the right one for your product or project. Also, Foam density and firmness are important, so be sure to check those out too.